The Panfix™ Quality

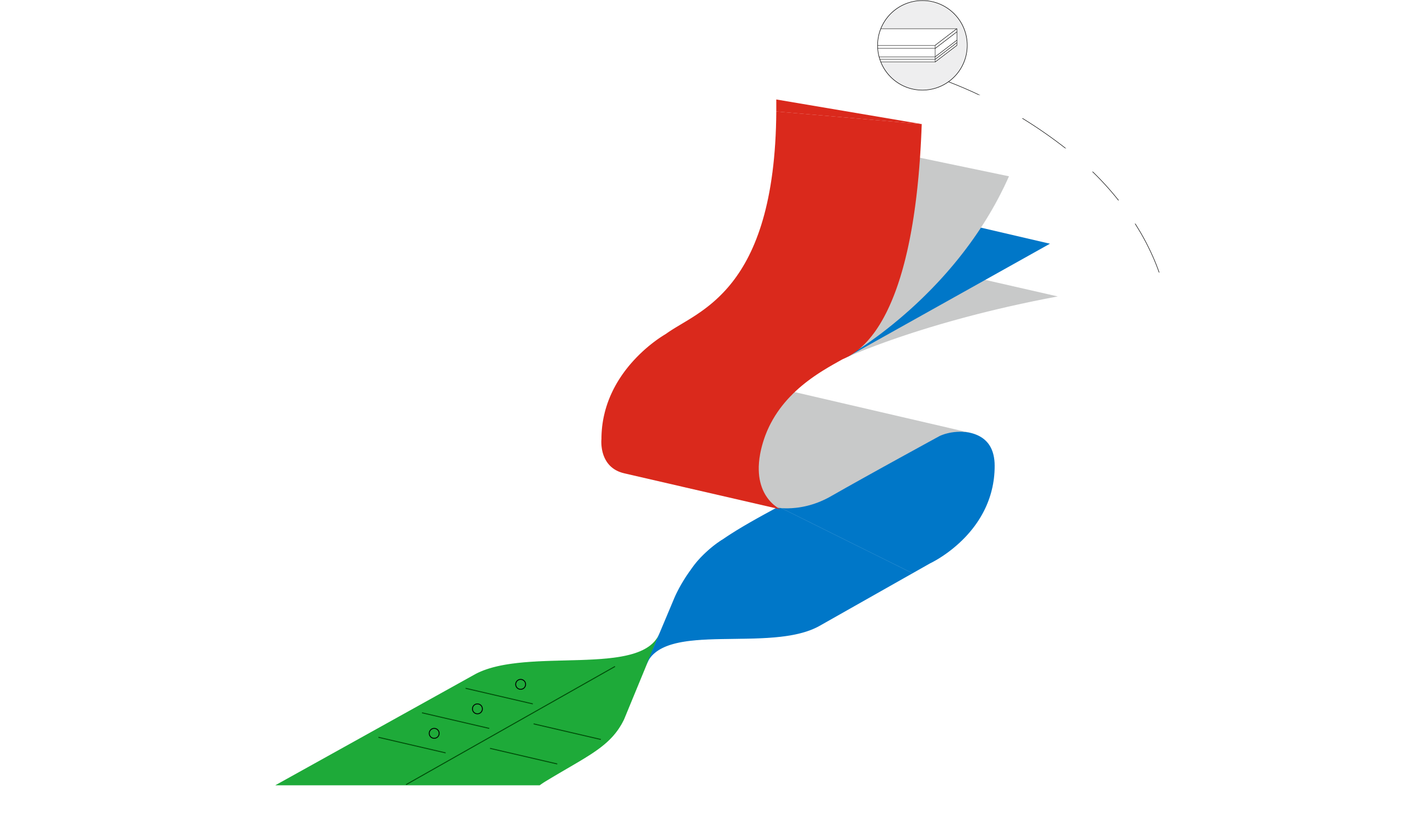

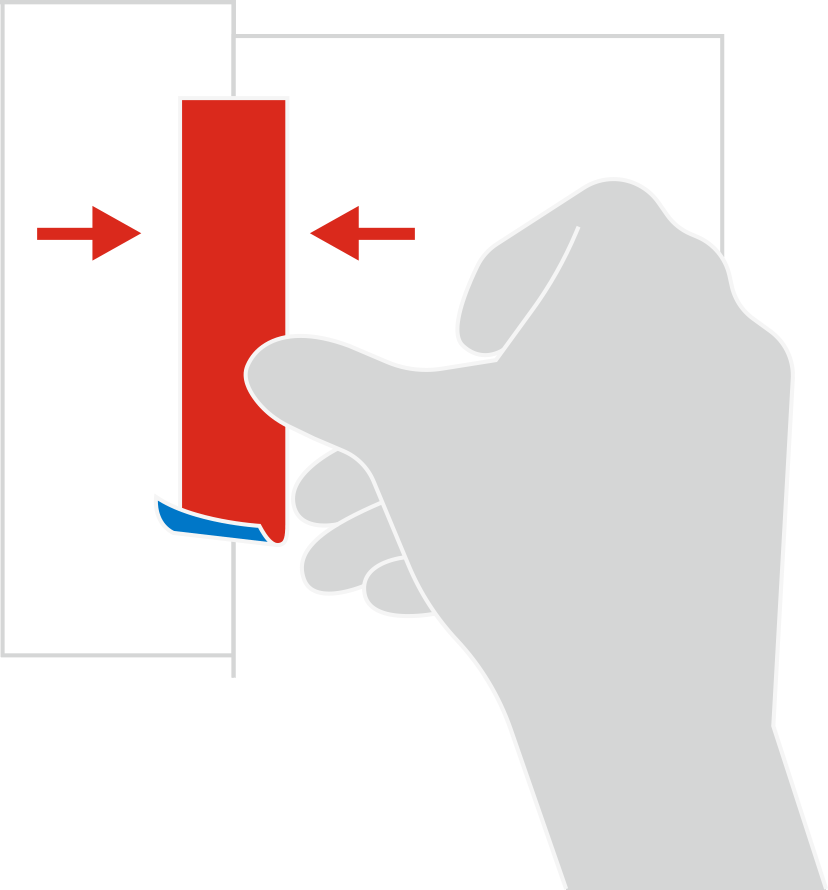

4-layer

structure

1. Release agent

2. Cellophane

3. Primer

4. Adhesive

Strong

Holding on tight.

Strong adhesive strength means it can stick to anything and won’t come off.

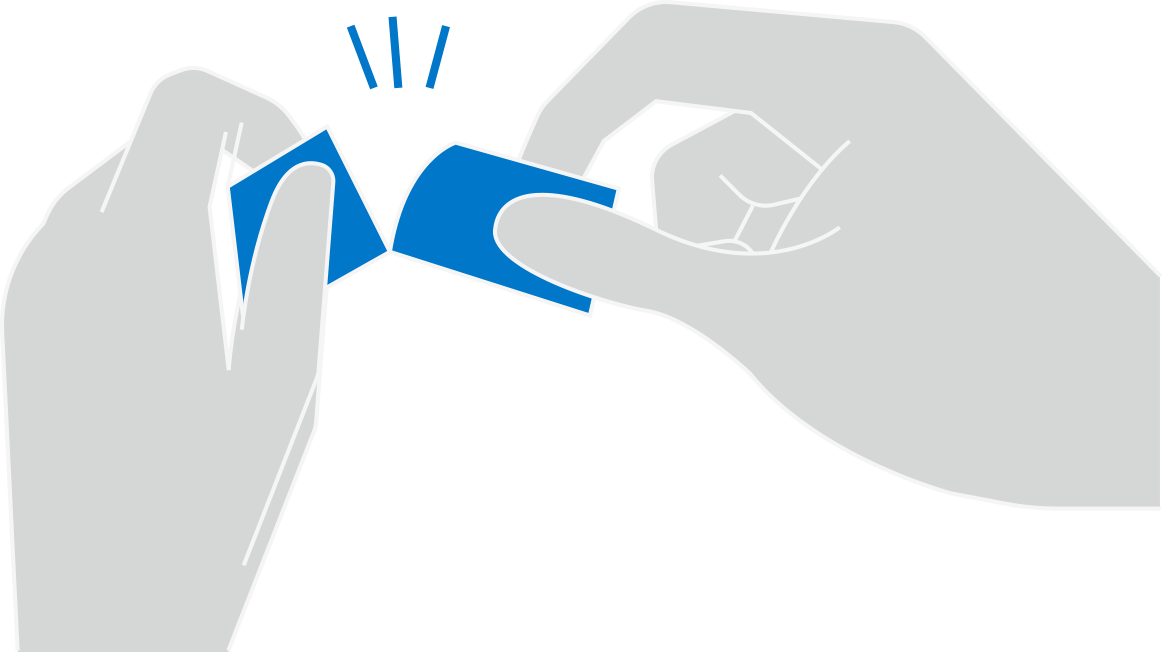

Smooth

No more sticky situations.

Our tapes are strong but easy to cut with your hands unlike OPP tapes.Also low level of static electricity reduces attraction to paper.

Soft

A Peace of Mind.

We make our tapes for everyone: you, your family,and the Earth. Because Nichiban tapes are made with natural,renewable ingredients like wood pulp, they are both eco-friendly and child-friendly.

Cellophane made from wood pulp

Core made from recycled paper

Adhesive made from natural rubber / resin

Holding on tight.

Strong adhesive strength means it can stick to anything and won’t come off.

No more sticky situations.

Our tapes are strong but easy to cut with your hands unlike OPP tapes.Also low level of static electricity reduces attraction to paper.

Safety comes first.

We make our tapes for everyone. Since they’re made with natural ingredients like wood pulp, you can let your kids use them without any health concerns.

What makes us different

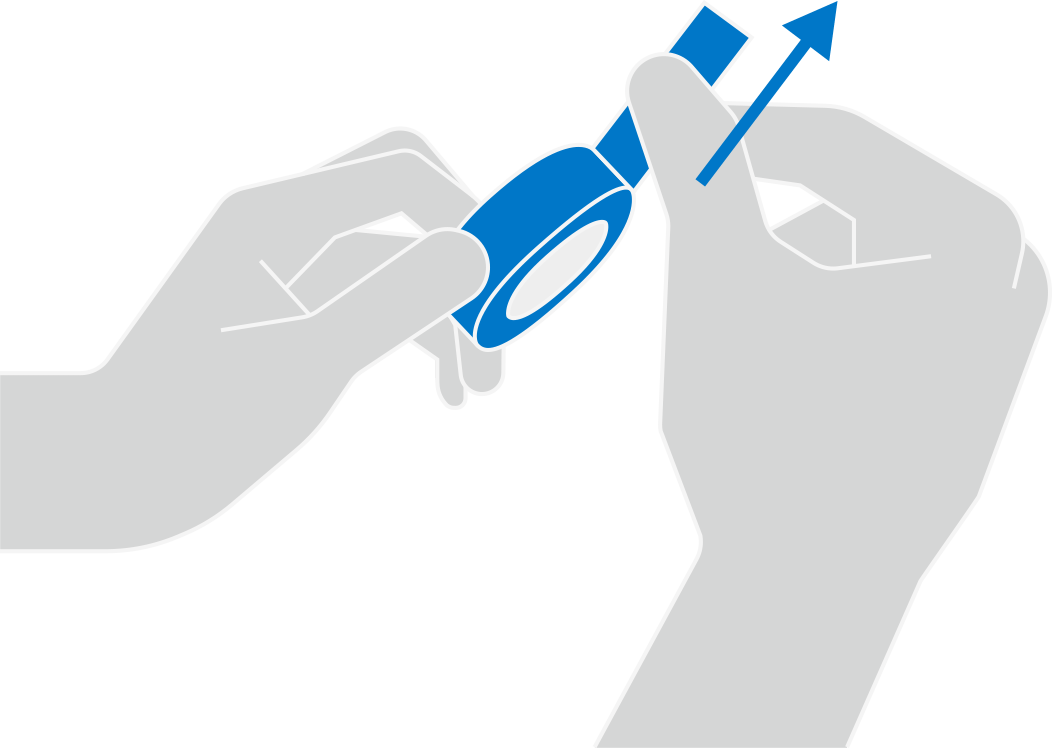

Smooth Operation

Special coating on top makes it easy to

pull out the tape.

Clean & Quick

Delicate work? No problem. Our non-static

tape promises clean and beautiful finishes.

Sticks like magic.

Our tapes aren’t affected by

temperatures and will stick to any

material.

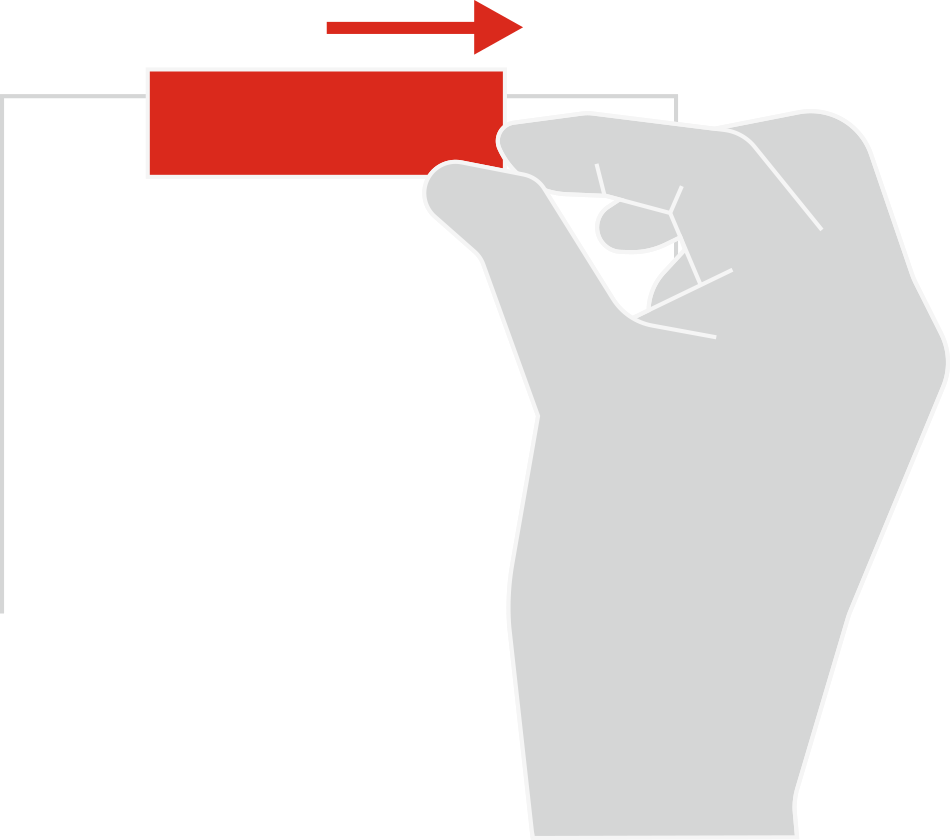

Easy tear

No scissors needed. Nichiban tapes can be

torn with your hands.

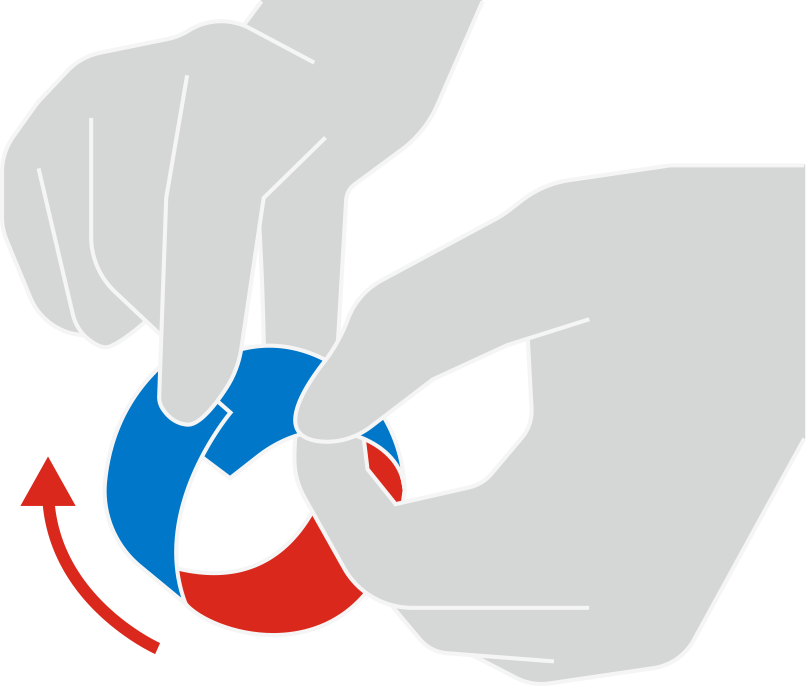

Roll it up

Or use the tape in any way you wish.

Natural materials are key ingredients for

making a self adhesive cellulose tape.

Wood pulp

Melt wood chips with chemicals and process them into wood pulp. When wood pulp is chemically reacted, it becomes transparent cellophane film.

Natural rubber

This is the main component of the adhesive. It is made by purifying and solidifying the rubber tree sap.

Natural resin

This is the tackifier of the adhesive. It is plant-derived resin such as pine resin.

How Cellulose Tape

is Made

1

Manufacture of cellophane

The raw material of cellophane is a wood chip. From the wood chips you can clump up vegetable fibers called “pulp”. By melting the pulp to cause a chemical reaction, a transparent cellophane film is made. The cellophane is created in a specialized factory for cellophane manufacturing.

2

Production of

pressure sensitive adhesive

The main raw material of the adhesive is natural rubber which can be taken out from the rubber tree. Cut the lumps of natural rubber that arrived from the production area, stretch them many times with rollers and process them thinly and softly. Put the processed rubber in a kettle together with natural resin and stir for about half a day to prepare an adhesive.

3

Processing of cellophane

We will process to cellophane arrived from a specialized factory. The surface of cellophane is coated with a release agent, the primer agent on the reverse side, and an adhesive, and it becomes a tape of 4 layer structure. Dry in a dryer and take up.

4

Cutting /

inspection / shipment

Cut the tape wound on a long tubular winding core to a certain width so as to cut the roll cake. We inspect the weight in order to make sure how many are packed in one package, and pack it in a box. Self Adhesive Cellulose Tape stored in the warehouse will be shipped worldwide in order.

Interview with our factory workers -Their passion for providing better PanfixTM Cellulose Tapes to customers [Part 1]

Our Panfix™ cellulose tapes are manufactured in a factory in Thailand. We interviewed three workers who actually work at the production site. This time, we will introduce an interview with one of our coating process worker.

[Interviewee]

-Male, working at coating process

Q1. How long have you been involved in the production of Panfix™ cellulose tapes? What processes are you in charge of this product?

- I have been in charge of coating process for 23 years since I joined the company. I have been spending my whole career in coating.

In the coating process, cellophane film is coated with release agent on surface and coated with primer and adhesive on the back.

Here, cellophane film as base material and coated tape are checked by the QC department, and only pass the Nichiban quality standards will proceed to the next process.

Q2. What are you actually in charge of in the coating process?

-In the coating process, I reel in the cellophane film provided by suppliers. I approximately make several dozen rolls per day.

Q3. What are you careful about while you’re working?

- I continue to work hard every day to provide high quality cellulose tapes to customers.

Cellulose tapes are very sensitive to humidity. The lower humidity is, the more likely tapes break. I always pay attention to keep the humidity of the workplace with hygrometer.

Q4. Message to the Customers

-We work hard every day to provide high quality cellulose tapes to customers.

Our Panfix™ cellulose tapes are chosen by a wide range of industrial enterprises and factories from food manufacturers to gift companies due to their unique features such as strong adhesive, ease of cutting quickly with less power, low static electricity, smell-less and so on.

It would be greatly appreciated if you could use our Panfix™ cellulose tapes.

Interview with our factory workers -Their passion for providing better PanfixTM Cellulose Tapes to customers [Part 2]

After the last time, we will introduce an interview with our cutting process worker.

[Interviewee]

-Female, working at cutting process

Q1. How long have you been involved in the production of Panfix™ cellulose tapes? What processes are you in charge of this product?

- I have been in charge of cutting process for 12 years since I joined the company. I spend my whole career in cutting. I cut countless cellulose tapes every day.

Q2. What are you actually in charge of in the cutting process?

- In the cutting process, a large roll of cellulose tape is cut into a product size.

Cellulose tapes are cut in two ways.

One is the slicer method that we cut a wide rolled cellulose tape with core into thin pieces (usually 12-24mm width size).

The other is the slitter method that we cut the cellulose tape, which has been rolled, into thin pieces while rewinding it, and roll it up on a core that has been already cut into a product size (usually 12-24mm width size).

Q3. What are you careful about while you’re working?

-It’s very basic, but I ’m trying to care about two points.

First one, as we cut multiple products of different sizes every day,

I always check the product specifications before starting cutting of different products.

Second one, I always take great care in accurately applying the tape to the paper core that is already cut according to the size of the product.

Q4. Message to the Customers

- I am so happy that cellulose tapes we made are used by consumers.

As our Panfix™ cellulose tapes are made from natural materials and they are eco-friendly products, and we have confidence in the quality of cellulose tapes we made.

I'd be grateful if you could choose and try to use our Panfix™ cellulose tapes.

Interview with our factory workers -Their passion for providing better PanfixTM Cellulose Tapes to customers [Part 3]

This time, we will introduce an interview with one of our Quality Control worker.

[Interviewee]

-Female, working at Quality Control

Q1. How long have you been involved in the production of PanfixTM cellulose tapes? What processes are you in charge of this product?

-I’ve been working for this company for five years. Since I joined the company, I have been in charge of quality check of PanfixTM cellulose tapes at the Quality Control.

Q2. What are you actually in charge of in the Quality Control?

-The Quality Control is an important task for checking the quality of manufactured products.

We will test PanfixTM cellulose tapes at various points from materials received to finished products on the basis of our company quality standard.

If the test result does not meet our quality standard, it will be determined to be defective and remade. And we will take necessary measures so that it won’t happen again.

Q3. What are you careful about while you’re working?

-I always try to proceed accurately and carefully in the course of day-to-day activities. PanfixTM products are put on the market as products after our Quality Control’s check.

An oversight on my job may cause quality problem and bring trouble to our customers. I’ll do my best efforts on my job to oversee no quality problem.

Q4. Message to the Customers

-Our company have a high standard of quality control. Therefore, I can confidently recommend our PanfixTM cellulose tapes are safe to use.

It would be much appreciated if you could use our PanfixTM cellulose tapes and give us some advice for help to improve quality of our products.

I will work even harder and keep getting better for improving the quality of our products.